The year 2021 has been lively and unsettling in equal measures for the Manufacturing Industry. While manufacturers are still recovering from the COVID 19 Pandemic, one has come to understand that change is the only constant and that there is always an opportunity in adversity.

The Corona Virus Pandemic has left the Manufacturing Sector grappling with multiple challenges like shortage of labour, disruption of supply chain, skill retention, and lack of new talent coming forth. Let us look at how firms are aligning their key business priorities for 2022 as manufacturers get back on track after this global upheaval.

ADDRESS & MANAGE SUPPLY CHAIN ISSUES

While global businesses are more efficient than they were a year ago, manufacturers are still impacted by logistical bottlenecks. Supply chain bottlenecks and delays are expected to last until 2022, due to a global shortage of materials and high energy costs. Manufacturing firms are experiencing distribution delays, particularly in international supply chain networks. According to Bloomberg, the cost of shipping a container from Asia to Europe has seen a tenfold increase since 2020. Customer service of manufacturers is severely impacted due to material shortages. For manufacturing firms, improving customer satisfaction is a top priority for the next 12 months. Therefore, a robust supply chain is an immediate manufacturing goal for 2022.

A NEW APPROACH TO INVENTORY MANAGEMENT

Disruptions in the supply chain are also impacting how firms make purchase decisions. Just-in-time inventory is giving way to just-in-case stocking as corporations stockpile raw materials and critical components to protect production schedules. Manufacturers will need to spend more time obtaining and stockpiling the correct components to avoid manufacturing delays.

EMPLOYEE RETENTION & ATTRACTING NEW TALENT

In order to address the labour shortage in manufacturing, it is vital to attract and retain younger workers as well as those who have returned to the workforce following the pandemic. It is equally important to plug skills gaps when seniors who have gained knowledge and hands-on experience retire. Concurrently, automation of production and use of robotics are creating a demand for new roles and skills. To close the skills gap and keep up with demand, manufacturers must attract new workers and increase employee retention. Creating a career roadmap during the interview process is an excellent way to show employees that the company is concerned about their future. In 2022, the manufacturing sector is likely to reconsider its approach to the employee life cycle.

CYBER SECURITY

In the last year, high-profile cyber-attacks across businesses and governments have raised cyber security as a risk management need for most CEOs and boards. During the pandemic, rising threats increased the commercial risk for manufacturers in the form of ransom ware. In the last 12 months, the majority of US manufacturers have reported phishing or ransom ware security problems. Additionally, insider threats are on the rise as a result of workforce displacements. Cyber security both within and outside of businesses is becoming increasingly important. Cyber criminals may wreak harm by intellectual property theft and inflict financial losses by employing malware that now incorporates Artificial Intelligence and crypto currency. They can also halt operations and disrupt whole supplier networks, jeopardizing both safety and efficiency.

Manufacturers should consider not just their cyber defences, but also their business’s survivability in the case of a cyber-attack. According to a Deloitte poll, 85% of CEOs anticipate their firms to invest more in preventive cyber security in 2022.

EMPHASIS ON AUTOMATION

Automation is also critical in assisting firms in compensating for a labour shortage and eliminating time-consuming and error-prone operations – from the plant floor to the back office. AI, machine learning, and smart machines can enhance decision making, quality, consistency, and availability.

ADOPTION OF ERP TECHNOLOGY AS END TO END SOLUTION

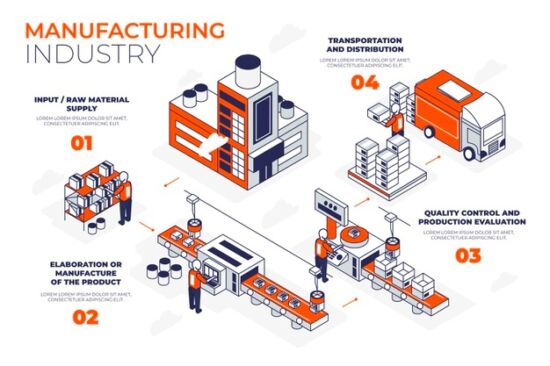

There are challenges and bottlenecks throughout the supply, production, and distribution process, from sourcing raw materials to delivering finished products to customers. As a result, manufacturers recognize the importance of a unified strategy and end-to-end optimization in order to solve these disparate issues. It would be simple to look at each minor issue individually, selecting a niche system to improve performance. However, this results in a significant increase in operational complexity and technical integration for manufacturing organizations to manage.

It is not only simpler and less expensive to integrate operations through manufacturing ERP than it is to use several systems; it also creates the degree of data and process integration required to give the business-wide, real-time insights that companies need. Manufacturing staff may make educated decisions in important areas such as the supply chain by boosting data visibility and business intelligence, allowing them to meet customer expectations and enhance satisfaction levels. In the aftermath of the disruptive impact of the pandemic, ensuring that digital transformation produces actual performance improvement and company success.

In 2022, businesses will prioritize the use of end-to-end solutions, such as manufacturing ERP software, that provide both wide advantages and focused enhancements.

BUSINESS TO CUSTOMER

Manufacturers are attempting to shift away from the Business to Business (B2B) model towards the Business to Consumer (B2C) model. When a business sells to a major distributor or a large retail shop, for instance, they lose a considerable amount of earnings and consumer data. As a result, several manufacturers are investing millions into user-friendly ecommerce platforms that link with their websites. By avoiding distribution middlemen, they can connect with their clients more directly, allowing them to effectively advertise their maintenance subscription models on their new products and gain more recurring business. Manufacturers that want to be successful in this field in the future must invest in customer service, sales, marketing, and their online ecommerce platform.

RENEWED FOCUS ON REDUCED CARBON FOOTPRINT & SUSTAINABILITY

Climate change has emerged as a critical issue for the manufacturing security. Manufacturing accounts for around one-third of global greenhouse gas emissions, prompting businesses to reconsider their business models and shift toward low-carbon or carbon-neutral manufacturing processes. Governments are making significant progress toward sustainability, investing heavily in climate change mitigation. These rules will need a transformation of manufacturing’s end-to-end processes, from product design and delivery to factory models.

It is now a corporate responsibility to manage operations in a sustainable and ecologically responsible manner. Many in the sector are already creating economically and ecologically sustainable business methods as the cost of energy and materials rises, laws tighten, and customers and investors move toward more sustainable brands and business practices. Expect this tendency to continue as more manufacturers connect the links between sustainability and earnings.

ON A FINAL NOTE…

The Manufacturing Industry trends mentioned in this article are simply a sliver of the trends that we have identified. Advanced manufacturing techniques and sustainable manufacturing will revolutionize the manufacturing industries as we know them now. Identifying new prospects and developing technology to incorporate into operations early on can help a company acquire a competitive advantage.

At ATC Online, we offer customized automation and ERP Solutions that are ideally suited for a wide array of operations in the Manufacturing Sector. To learn more about our Manufacturing Automation ERP technologies, please visit us at: https://atconline.biz/products/pacifyca-manufacturing-resource-planning-system-mrp-ii/